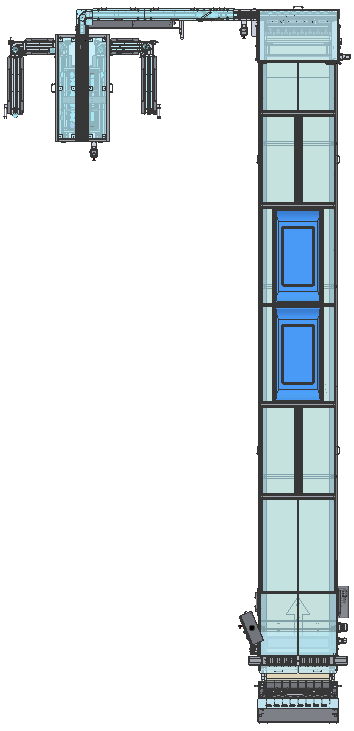

Our highest-speed dish-filling machine has a space-saving design with 100% open dish drying, all enclosed in a HEPA-filtered environment. High-speed stacking using our drop stacking technique avoids stack tip-over and other issues found with conventional stackers.

Work with our engineers and receive high-quality customer service and machinery to fit the needs of your space and production needs.

| Dish Type | 4 Lane | 8 Lane | 10 Lane |

|---|---|---|---|

| Mono-plate | 6,000 | 12,000 | 15,000 |

| Bi-plate | 4,000 | 8,000 | 10,000 |

| Contact/ RODAC | 6,000 | 10,000 | 12,500 |

Machine Specs:

- Up to 1,500 dishes per hour, per lane – custom lane counts available

- Aluminum/Stainless steel construction

- Mono/Bi plate pouring

- Adjustable lids-off dry time

- Meniscus generation

- Touch panel user interface

- Requires one operator when using automated packaging, two or more with manual packaging

- Requires 50/60Hz, 115/230VAC single phase power

- Pneumatic control included as standard, servo control optional

- Housed in a HEPA-filtered mini environment

- Media delivery through the use of peristaltic pumps

Other Options Available For Purchase:

- Individual nozzle volume control

- Bulk loader

- Rotary edge printing

- Passive edge printing

- Nozzle heating

- Packaging